PRODUCT DESIGN SERVICES

Have an innovative product concept you’re eager to bring to life? Our expert Product Design Services are here to help you turn your ideas into tangible, market-ready solutions. We begin by engaging with your team to fully understand your vision, target market, and application requirements. Our process starts with in-depth concept development, exploring aesthetics, functionality, and user experience. Once a clear direction is established, our experienced engineers take over to craft detailed CAD models and mechanical designs. We pay careful attention to component selection, manufacturability, and compliance with applicable standards. Throughout the development phase, we keep you closely involved, encouraging feedback and collaboration. Prototyping follows, allowing for functional and visual testing, and fine-tuning before committing to mass production. We also offer assistance in testing for durability, reliability, and regulatory requirements. Whether you're a startup building your first product or an OEM expanding your portfolio, our end-to-end design service ensures a smooth path from concept to creation. Partnering with us means your ideas are supported by a team driven by innovation, precision, and excellence.

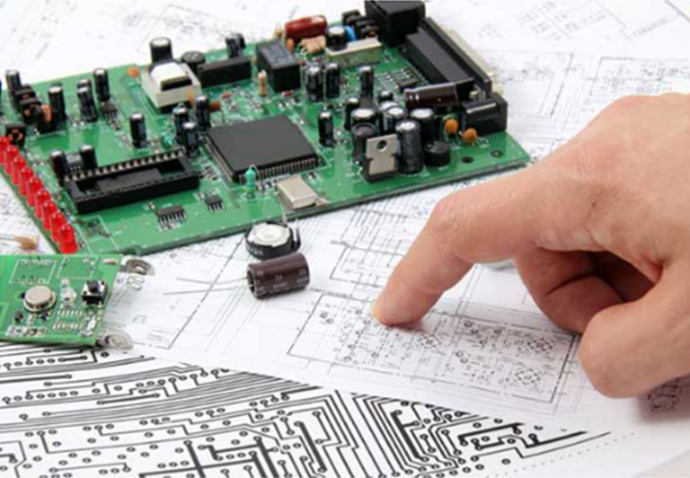

EMBEDDED SYSTEMS

Excel Eltech offers comprehensive embedded systems design and development services tailored for a wide range of applications including defense, industrial automation, medical devices, and consumer electronics. Our expertise spans across microcontrollers, microprocessors, FPGAs, and DSPs, with support for multiple architectures and platforms. We design both hardware and firmware, integrating real-time operating systems (RTOS), wireless connectivity, and sensor interfaces. Our solutions are optimized for performance, power efficiency, and reliability. We support rapid prototyping and validation using simulation tools and evaluation kits. From board bring-up to application-level software, our team ensures seamless integration and testing. We also assist in compliance testing and certifications required for mission-critical and safety-oriented systems. Excel Eltech acts as a dependable embedded technology partner from idea to implementation.

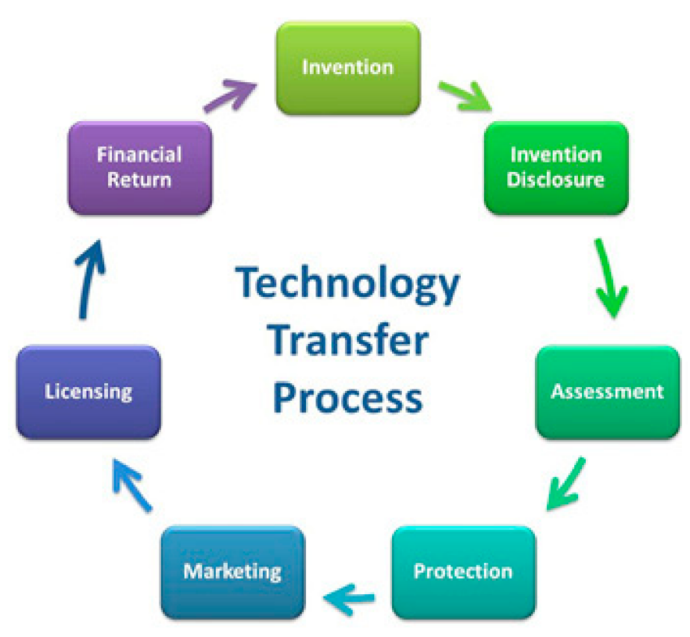

TOT PROJECTS (TRANSFER OF TECHNOLOGY)

Excel Eltech actively collaborates on Transfer of Technology (ToT) projects, especially in the defense and aerospace sectors where indigenous development is critical. We support complete absorption, adaptation, and scaling of transferred technologies to suit local production and customization needs. Our team ensures smooth knowledge transfer, process documentation, training, and tool qualification to make the project a success. We have experience in adapting imported technologies to meet Indian environmental and operational standards. We also provide component localization and value engineering to improve cost-effectiveness and maintainability. With strong project management and technical execution, we bridge the gap between technology originators and local application needs. Excel Eltech ensures that ToT projects are executed with full compliance, efficiency, and knowledge retention. This supports India’s mission of self-reliance and technological independence.

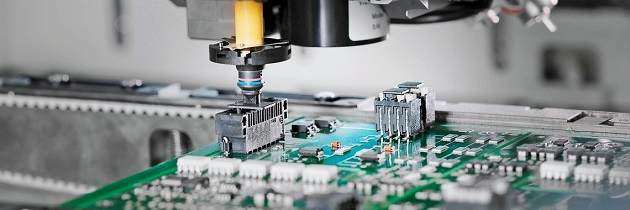

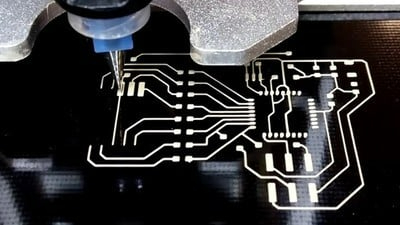

BUILD TO PRINT

Under our Build to Print service, Excel Eltech offers precision manufacturing of electronic systems and assemblies exactly as per customer-provided drawings, specifications, and BOMs. We ensure strict adherence to design intent, quality requirements, and traceability. Our team meticulously reviews all engineering documents for manufacturability and process optimization. From PCB assembly and wire harnessing to full system integration and testing, every stage is executed using certified processes and controlled work instructions. We serve industries where confidentiality, accuracy, and repeatability are paramount, such as aerospace, defense, and medical. With robust quality control and full compliance with IPC/MIL standards, we ensure products are production-ready and audit-compliant. Excel Eltech also manages component sourcing and lifecycle support for Build to Print projects. Customers rely on our infrastructure, experience, and discipline to bring their documented designs to life.

CONCEPT TO PRODUCT

Excel Eltech provides full-spectrum support from concept to finished product, enabling customers to transform innovative ideas into tangible, market-ready solutions. We start with requirement analysis and architecture design, followed by hardware, firmware, and mechanical development. Our engineering team brings together functionality, usability, and manufacturability right from the design phase. We offer prototyping, testing, regulatory compliance, and DFM (Design for Manufacturability) to ensure smooth production scaling. The entire process is supported by our in-house manufacturing and assembly capabilities, allowing rapid transitions from design to deployment. We collaborate closely with customers at every stage, ensuring technical alignment and cost optimization. With end-to-end ownership, Excel Eltech helps reduce time-to-market and design risks. This service is ideal for startups, product companies, and OEMs seeking reliable turnkey development.

APPLICATION-BASED VLSI SYSTEMS

Excel Eltech delivers high-performance VLSI (Very Large Scale Integration) based systems tailored for domain-specific applications such as signal processing, image recognition, communication, and aerospace computing. We design application-specific integrated circuits (ASICs), system-on-chip (SoC), and FPGA-based platforms optimized for power, performance, and area. Our VLSI solutions are developed with a strong focus on functional verification, synthesis, timing analysis, and post-silicon validation. We support both frontend and backend VLSI design with deep knowledge of EDA tools and semiconductor technologies. These systems are crucial for edge computing, defense-grade cryptographic engines, and real-time control systems. Excel Eltech ensures that the hardware design aligns with the software stack for complete system integration. We partner with fabless semiconductor companies and foundries to manage the complete lifecycle—from RTL to GDSII and tape-out. With strong application know-how and silicon-proven experience, Excel Eltech enables innovative VLSI-based product development.

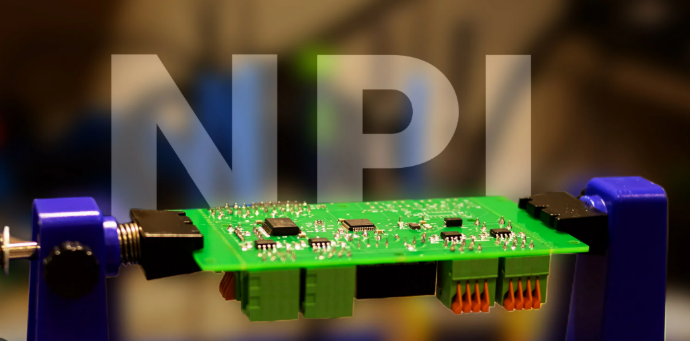

NEW PRODUCT INTRODUCTION (NPI) SERVICES

Launching a new product can be a complex journey, but our New Product Introduction (NPI) services streamline this process to help you move from prototype to production swiftly and successfully. Our proven methodology prioritizes speed, precision, and efficiency while maintaining strict control over quality and cost. We assign a dedicated project launch team to each client, ensuring personalized attention and accountability from start to finish. From initial design verification to supply chain readiness and pilot runs, we manage every phase with meticulous detail. Our cross-functional expertise spans design validation, tooling, DFM/DFA analysis, and regulatory compliance. We utilize robust planning and tracking tools to monitor timelines and ensure every milestone is met. Frequent status reviews and transparent communication help you stay informed and in control. We are especially equipped to handle time-sensitive or high-volume product launches, with the scalability and infrastructure needed for rapid expansion. Our experience across industries—from electronics to industrial equipment—enables us to anticipate and address potential bottlenecks early. With us, you can confidently introduce innovative products into the market, knowing you have a team of experts driving your success.

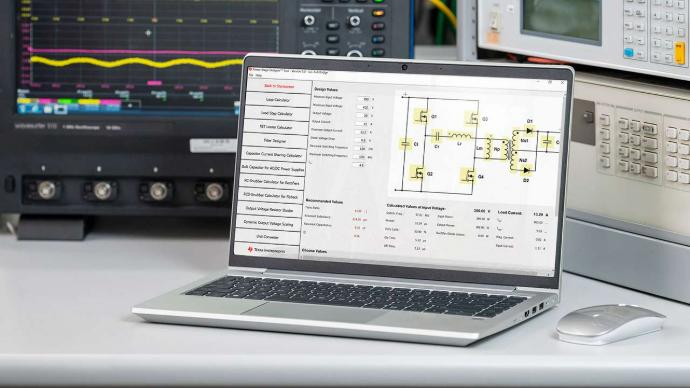

DESIGN & SIMULATION TOOLS

Designing modern products requires more than creativity--demands the right tools to validate performance, optimize systems, and reduce development time. Our advanced Design & Simulation Tools offer just that, enabling you to bring better products to market faster and more cost-effectively. Whether you're evaluating component alternatives, analyzing signal integrity, or running thermal simulations, our tool suite supports all phases of design. We use industry-leading software platforms to perform structural, electrical, and mechanical simulations, helping predict how products will behave under real-world conditions. This virtual prototyping capability reduces the need for multiple physical iterations, saving time and resources. In addition, our tools support failure mode analysis, tolerance stack-up assessments, and stress analysis to ensure reliability. Integrated simulation allows us to optimize product architecture before a single prototype is built. We also provide detailed simulation reports and data to support design decisions and compliance documentation. With faster iteration cycles and greater confidence in outcomes, our clients experience fewer redesigns and quicker time-to-market. These capabilities empower both startups and enterprises to make smarter design decisions with measurable results.

OTHER SERVICES – INDIGENIZATION

In today’s evolving global landscape, the ability to localize product components and systems has become more crucial than ever. Our Indigenization Services focus on reducing dependency on imported parts by developing and sourcing equivalent components domestically. We work closely with clients in defense, medical, railway, industrial, and commercial sectors to identify and re-engineer legacy parts or systems for local production. This not only helps achieve cost-effectiveness but also enhances supply chain resilience and ensures compliance with governmental policies like “Make in India.” Our team conducts comprehensive analysis and reverse engineering, followed by detailed documentation, validation, and qualification. We maintain a strong network of local manufacturers and suppliers to ensure timely production and delivery. Whether it’s mechanical subassemblies, electronics, or complex integrated systems, we tailor solutions to match your performance, quality, and budget expectations. Indigenization also enhances long-term serviceability and availability of spare parts, which is crucial for mission-critical applications. By adopting a strategic approach, we help customers realize the full benefits of localization—technical, economic, and strategic. Choose us as your partner in building self-reliant and future-ready solutions.